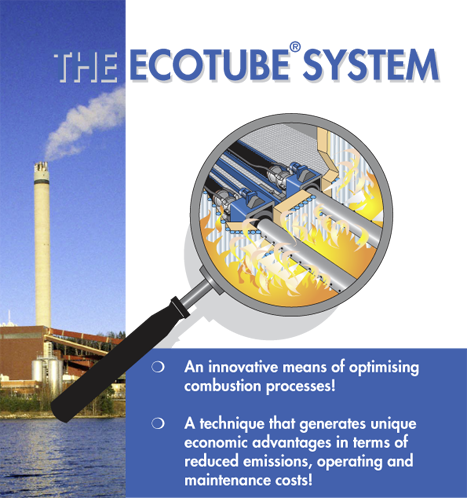

The Ecotube system represents an innovative cost-effective optimisation tool for combustion processes and principally comprises retractable lances - Ecotubes - that are equipped with injection nozzles. Various agents can be introduced through the nozzles at high pressure and velocity into the furnace media. The Ecotubes are strategically positioned within the furnace enabling the injected agents to create a radically improved mixing of the combustion products, resulting in destruction of laminar gas columns and the for¬mation of completely mixed turbulent flow patterns.

Ecotube system advantages by comparison with other emission abatement techniques:

• Engineered for retrofit applications

• Increased load capacity

• Lower plant operation costs

• Lower ID fan motor absorbed power

• Radically improved turbulence and mixing

• Reduced boiler-wall metal corrosion of combustion gases

• Reduced erosion of boiler convective surfaces

• Reduced NOx, CO, SOx, HCl and particles

• Minimum unit down time (3-4 days) needed in the flue gas for installation

• Lower stoichiometric ratio (less excess air)

• Lower maintenance costs in the furnace

• No large ducts or furnace modifications

• Increased thermal efficiency required

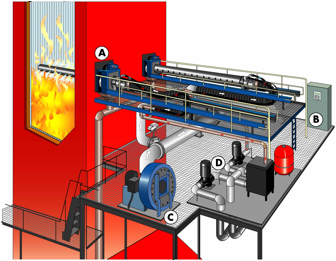

Four unique basic packages designed for every application:

A Ecotube assemblies

B Control system A

C Air supply system

D Cooling water system

|

|

A Each Ecotube is fitted with:

• transmission drive to insert and retract the Ecotube

• cleaning mechanism for automatic removal of furnace deposits from the Ecotube surface

B A plc based monitor and control system enables unmanned auto¬matic operation which is relayed to the regular control room for alarm and monitor functions.

|

|

C A dedicated high pressure process air system comprising skid mounted fan, ductwork and adjustable Ecotube distributed nozzles provides the increased flue gas turbulence and mixing within the furnace.

D The cooling water system which enables the Ecotubes to operate continuously within the furnace comprises a pump, a heat exchanger and auxiliary equipment. Extracted energy can be utilised for various purposes within the plant energy system.